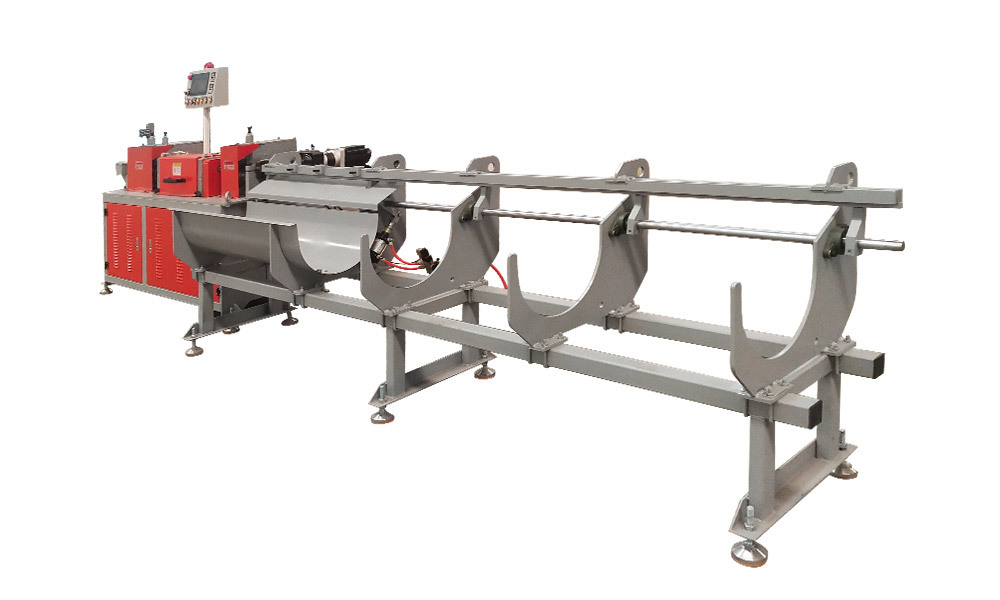

The main features of the high-speed straightening machine are simple operation, high efficiency, high straightening accuracy and low material loss. It can quickly stretch the metal material to make the surface flatness of the material meet the requirements, repair the defects and fatigue cracks on the surface of the material, and improve the strength and durability of the material.

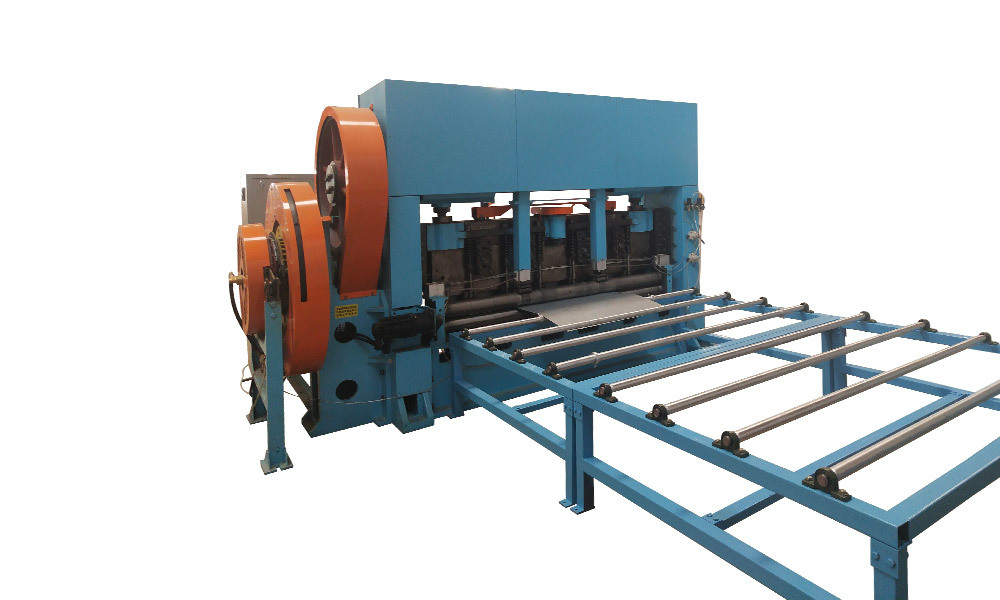

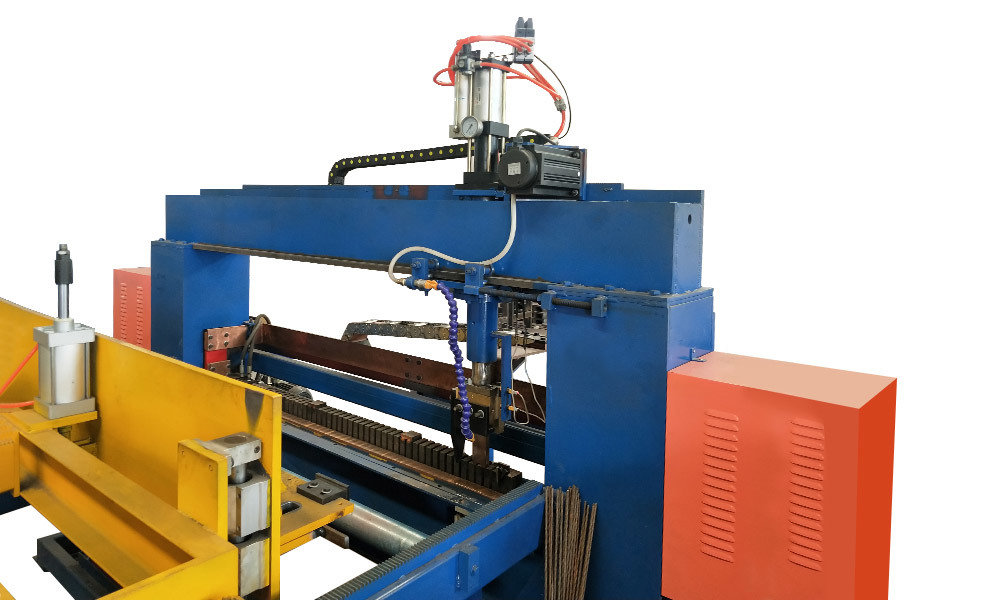

The working principle of the high-speed straightening machine is that the metal material is introduced from both sides through the upper and lower rollers and the transmission mechanism of the machine, and the material is stretched through the rotation of the rollers, and the position of the material between the rollers is adjusted to make the material The surface flatness meets the requirements.

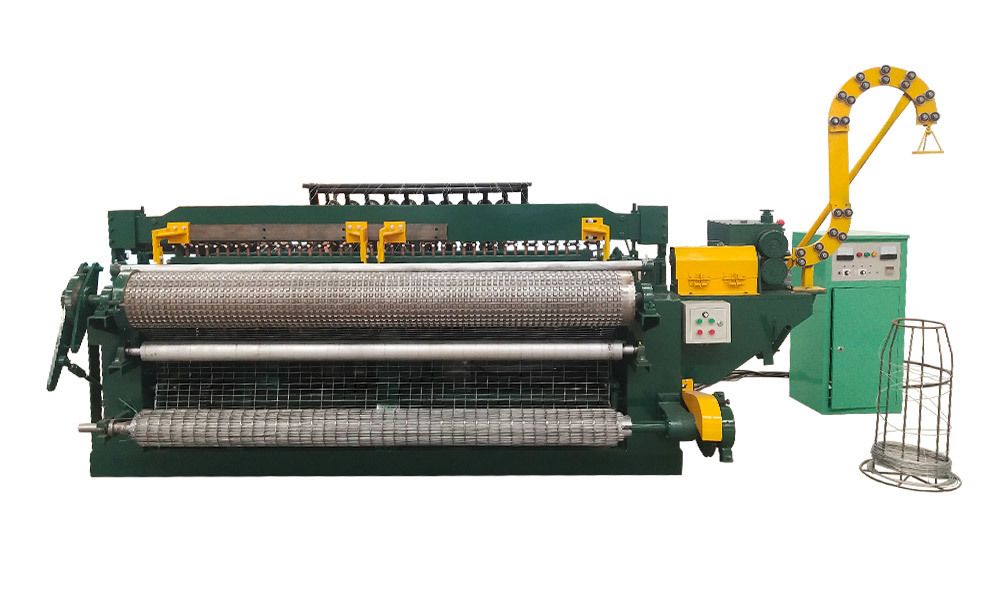

The main components of the high-speed straightening machine include the frame, rollers, transmission mechanism, control system and so on. Among them, the roller is a key component, which is usually made of high-strength alloy materials, which has the characteristics of wear resistance and corrosion resistance. The diameter and surface quality of the roller determine the working effect and straightening accuracy of the straightening machine.

The use method of the high-speed straightening machine is relatively simple. The operator only needs to put the metal material into the feeding device on the frame, and the straightening process can be carried out after starting the machine. Through the control system, the rotation speed and position of the roller can be adjusted to control the stretching force and straightening accuracy during the straightening process.

The advantages of high-speed straightening machine are fast processing speed and high straightening accuracy, which can meet the requirements of high surface flatness and dimensional accuracy of metal materials. At the same time, due to the stretching and trimming of the metal material during the straightening process, the strength and durability of the material can also be improved.

In short, the high-speed straightening machine is an important equipment for metal material processing, which makes the surface flatness and dimensional accuracy of the material meet the requirements by stretching, straightening and trimming the metal material. It is widely used in various fields to help improve the processing quality and performance of metal materials.

High speed straightening machine

Key words:

Classification:

Recommended Products

The company is located in Anping County, Hebei Province, a large wire mesh industry base in Asia, covering an area of more than 8000 square meters. Since its establishment for more than ten years, it has become a comprehensive research and development, production and wrong sale of various wire mesh machinery and equipment. enterprise.