|

Name

|

Content

|

|

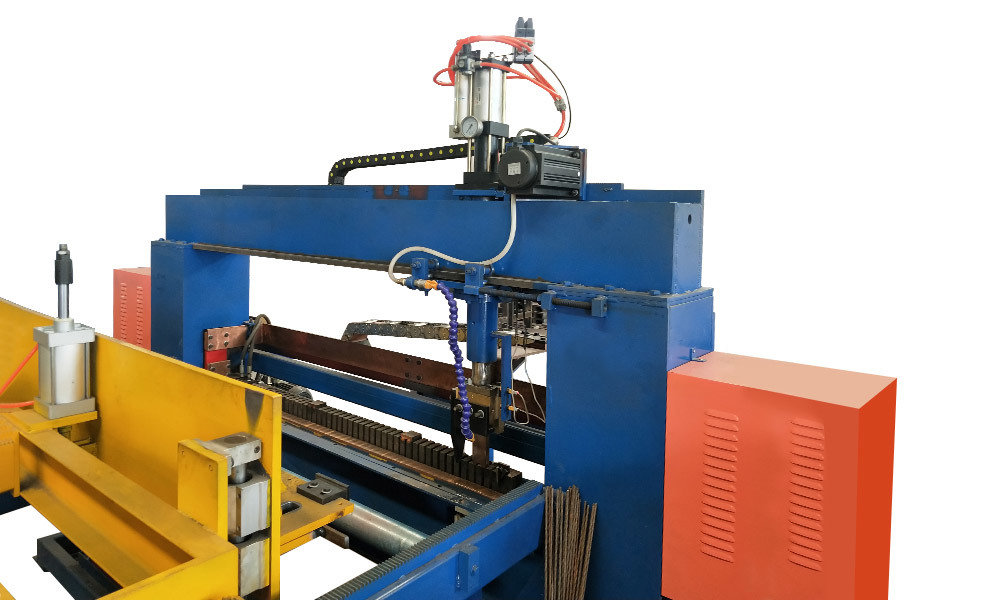

Maximum welding speed

|

40-100 times/min (cross bar spacing 50mm)

|

|

Maximum welding width

|

≤ 500mm or customized according to customer demand

|

|

Spacing of longitudinal bars

|

≥ 50mm (incremental) manual adjustment

|

|

Cross bar spacing

|

≥ 20mm computer setting

|

|

Diameter of longitudinal reinforcement

|

2.5-6mm

|

|

Diameter of transverse reinforcement

|

2.5-6mm

|

|

Maximum welding capacity

|

Diameter 6mm 6mm

|

|

Welding materials

|

The surface of ribbed reinforcement and round steel shall be free of rust and lime drawing agent.

|

|

Longitudinal bar feeding mode

|

Plate

|

|

Transverse bar feeding mode

|

Pre-cutting/automatic blanking (straightness 2 mm/M)

|

|

Transformer power

|

2*100kVA

|

|

Load persistence rate

|

20%

|

|

Power supply voltage

|

380V±10%

|

|

Air supply pressure

|

0.6-0.8MPa

|

|

Cooling water pressure

|

0.3MPa 15L/min

|

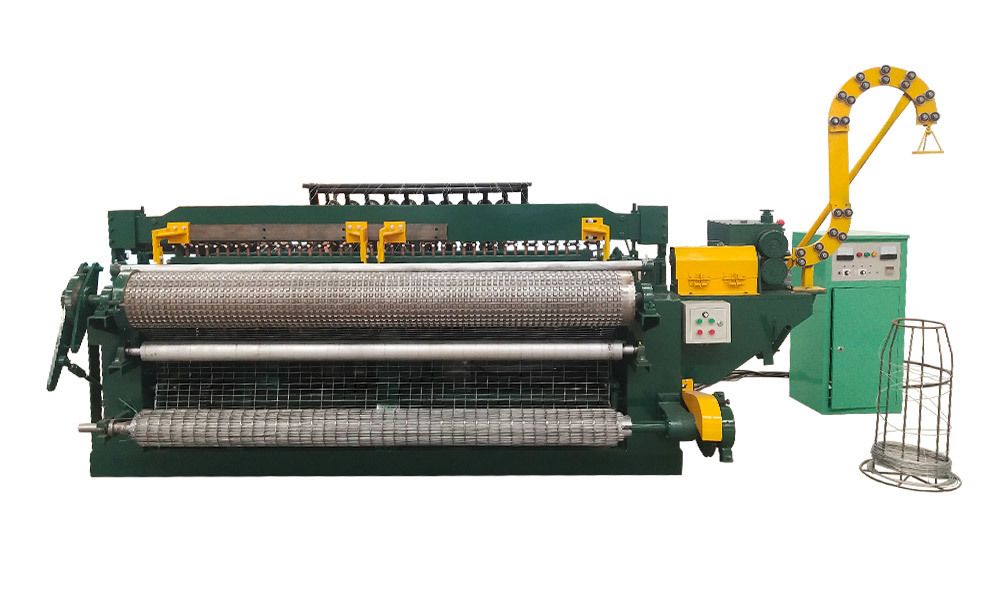

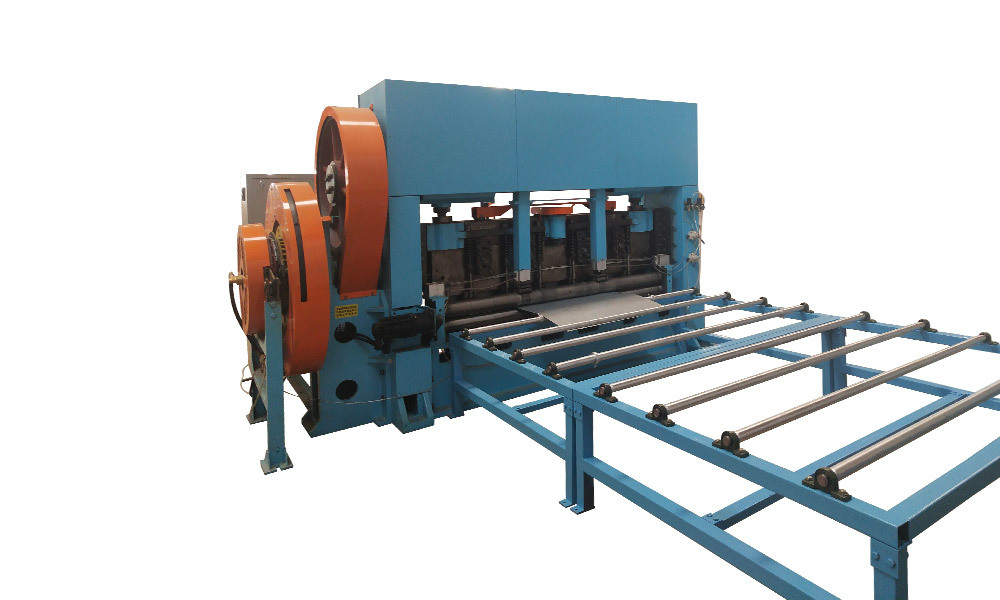

Aerated plate welding net machine is a kind of special welding net equipment for reinforcing aerated plate. Aerated board is a kind of lightweight and high-strength building material, but its fragility and brittleness make it prone to cracking and breakage during use. In order to solve this problem, it is necessary to cover the surface of the aerated plate with a layer of welded mesh to enhance its strength and stability.

Aerated plate welding mesh machine has the following characteristics and advantages:

1. Automatic operation: The gas-filling plate welding mesh machine adopts PLC control system, which can realize automatic welding process, reduce manual operation and improve production efficiency.

2. Precise welding technology: Using advanced welding technology, the welded mesh can be evenly welded on the surface of the aerated plate to ensure firm welding and precision.

3. Multifunctionality: The aerated plate welding mesh machine can also weld different specifications and sizes according to needs to meet the needs of different projects.

4. **Energy saving: The use of** electric and pneumatic systems can reduce energy consumption and production costs.

5. Stability and reliability: The aerated plate welding mesh machine adopts high-quality materials and structural design, has stable performance and reliable operation, and can work continuously for a long time.

Aerated plate welding mesh machine is one of the indispensable equipment in the modern construction industry, which can improve the strength and stability of the aerated plate and ensure the safety and quality of the building. With the development of construction industry, the application prospect of aerated plate welding mesh machine is more and more broad.

Aerated Plate Welded Mesh Machine

Key words:

Classification:

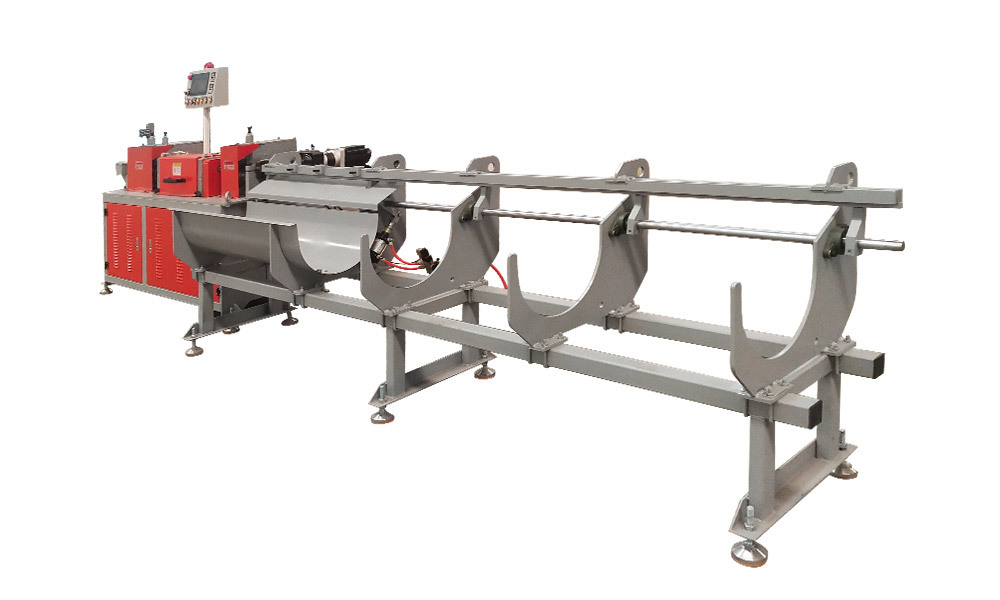

Recommended Products

The company is located in Anping County, Hebei Province, a large wire mesh industry base in Asia, covering an area of more than 8000 square meters. Since its establishment for more than ten years, it has become a comprehensive research and development, production and wrong sale of various wire mesh machinery and equipment. enterprise.